Sandwich roofing panels have emerged as a game-changing solution in modern construction, offering a blend of durability, insulation, and cost-efficiency. Whether you’re building a warehouse, commercial facility, or residential extension, these panels provide a smart alternative to traditional roofing systems.

In this guide, we’ll explore the construction, materials, installation, maintenance, and financial benefits of sandwich roofing panels, helping you make the most affordable and effective choice for your structure.

Understanding Sandwich Panel Construction

Sandwich roofing panels are engineered with a layered structure that enhances performance:

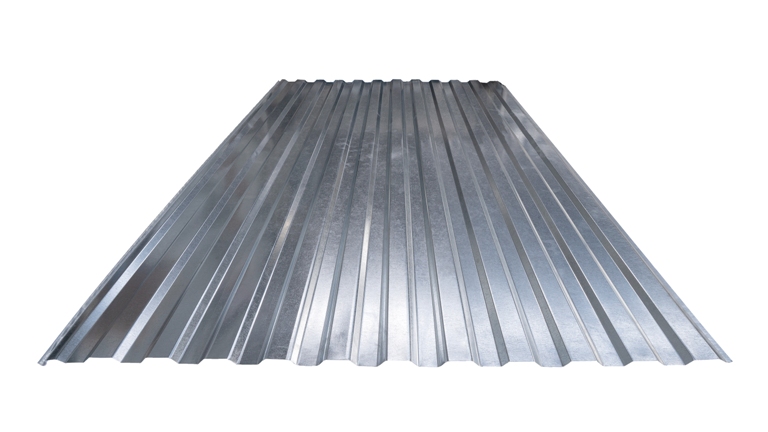

a. Outer Layers (Facings): Typically made of pre-painted galvanized steel, aluminum, or fiberglass, these layers provide structural strength and weather resistance.

b. Core Material: The insulating core is usually made of polyurethane foam (PUF), polyisocyanurate (PIR), expanded polystyrene (EPS), or mineral wool. This layer delivers thermal insulation, soundproofing, and fire resistance.

This “sandwich” design ensures that the panels are lightweight yet robust, easy to install, and highly energy-efficient.

Materials Used and Their Purpose

Sandwich roofing panels are composed of various materials, each selected for specific performance attributes. The outer facings are typically made from galvanized steel or aluminum, offering structural strength, corrosion resistance, and weather protection. The core insulating material varies depending on the desired thermal, acoustic, and fire-resistant properties.

Polyurethane foam (PUF) is widely used due to its excellent thermal insulation properties and lightweight nature, making it an ideal material for energy-efficient buildings. Polyisocyanurate (PIR), a close relative of PUF, provides even better fire resistance while maintaining strong insulation performance.

Expanded polystyrene (EPS) is a more budget-friendly option, offering moderate insulation and ease of handling, making it suitable for cost-conscious projects.

For applications requiring superior fireproofing and sound absorption, mineral wool is the preferred choice due to its non-combustible and dense composition.

Together, these materials enable sandwich panels to be customized for a wide range of structural and environmental needs, striking a balance between performance and affordability. Each material serves a specific need, from maximizing insulation to enhancing fire safety, allowing you to tailor your roofing solution to your project’s requirements.

Pre-Installation Considerations

Before installing sandwich roofing panels, proper planning is essential:

1. Site Assessment: Evaluate environmental conditions, load-bearing capacity, and structural design to ensure optimal performance.

2. Panel Selection: Select the panel thickness and core material based on your insulation needs and budget.

3. Supplier Verification: Ensure your supplier meets quality standards and offers certified products.

4. Logistics Planning: Schedule delivery and storage to prevent damage and delays.

A well-prepared site ensures smooth installation and long-term performance.

How to Install Sandwich Roofing Panels

Installation is relatively straightforward but requires precision:

1. Frame Preparation: Ensure the supporting structure is level and securely in place.

2. Panel Placement: Align panels carefully, starting from one end of the roof.

3. Fastening: Use self-drilling screws and sealing washers to secure panels.

4. Joint Sealing: Apply sealants or gaskets to prevent water ingress.

5. Edge Finishing: Install flashing and trims for a clean, weatherproof finish.

Professional installation guarantees optimal thermal performance and structural integrity.

Care and Maintenance Tips

Sandwich roofing panels are low-maintenance, but regular checks can extend their lifespan:

1. Annual Inspection: Check for signs of corrosion, loose fasteners, or degraded sealant.

2. Cleaning: Use a very mild detergent and water to remove dirt and debris.

3. Sealant Renewal: Reapply sealants every few years to maintain waterproofing.

4. Pest Control: Ensure no gaps or nesting areas for birds or rodents.

Routine care helps preserve insulation quality and aesthetic appeal.

Quality Control and Safety Measures

To ensure safety and compliance, follow these best practices:

1. Certified Products: Utilize panels that have been tested for fire resistance, thermal performance, and structural strength.

2. Installation Standards: Adhere to local building codes and manufacturer guidelines.

3. Protective Gear: Workers should use helmets, gloves, and harnesses during installation.

4. Weather Precautions: Avoid installation during heavy rain or high winds.

Quality control not only protects your investment but also ensures the safety of occupants.

Cost-Benefit Analysis and ROI Maximisation

Sandwich roofing panels offer significant financial advantages:

1. Lower Installation Costs: Quick setup reduces labor expenses.

2. Energy Savings: Superior insulation cuts heating and cooling bills.

3. Durability: Long lifespan minimizes repair and replacement costs.

4. Tax Incentives: Energy-efficient buildings may be eligible for rebates or tax credits.

Compared to traditional roofing, sandwich panels deliver a higher return on investment through reduced operational costs and enhanced building performance.

Final Thoughts: Smart Roofing Starts Here

Sandwich roofing panels combine innovation, efficiency, and affordability, making them an ideal choice for modern structures. By understanding their construction, selecting the right materials, and adhering to best practices for installation and maintenance, you can unlock long-term value and optimal performance.

Are you ready to upgrade your roofing system with high-quality sandwich panels? Visit ezibatten.com, your trusted partner for durable, cost-effective roofing solutions. Discover expert advice, premium products, and seamless support to ensure your next project’s success.

Recent Posts

Categories

- roofers bracket 3

- gutter accessories suppliers 9

- metal ceiling battens 5

- metal fascia for modern roof 1

- Uncategorized 9

- metal roof insulation blanket 1

- cladding building materials 2

- top hat roofing 2

- metal roofing suppliers 5

- gutter and fascia replacement 3

- metal roof batten 13

- top hat battens 1

- metal fascia 2

- steel roof batten 34

- roof battens and purlins 7

- insulated roofing panels 22

- sandwich roofing panels 15