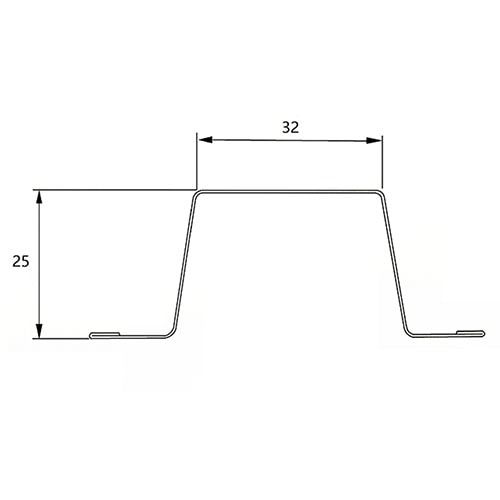

METAL CEILING BATTENS

When you need top quality, reliable ceiling / safety battens, Ezi-Batten has the right product for you.

When you need top quality, reliable ceiling / safety battens, Ezi-Batten has the right product for you.

Our Ceiling / Safety Battens are all made from strong and durable steel to keep your roof stable, control the movement in your rafters, and stop your ceiling plasterboard from cracking. For use on all types of domestic ceiling boards, our safety battens are lightweight, easy to install, and affordable.

Ezi-Batten manufactures top quality roofing materials for professional tradesman and roofing companies. We’re available for all your roofing requirements and you can take advantage of our experience in the roofing and sheet metal industry. Call us on 07 5449 8765 or contact us online for expert advice.